Understanding Plastic Injection Companies in the Manufacturing Sector

The world of manufacturing is vast and intricate, with numerous processes and techniques contributing to the development of high-quality products. Among these, the role of a plastic injection company stands out as a cornerstone in the production of plastic components. As we delve deeper into this industry, we will explore what sets plastic injection molding apart, its applications, benefits, and why partnering with a reputable firm like DeepMould.net is crucial for success.

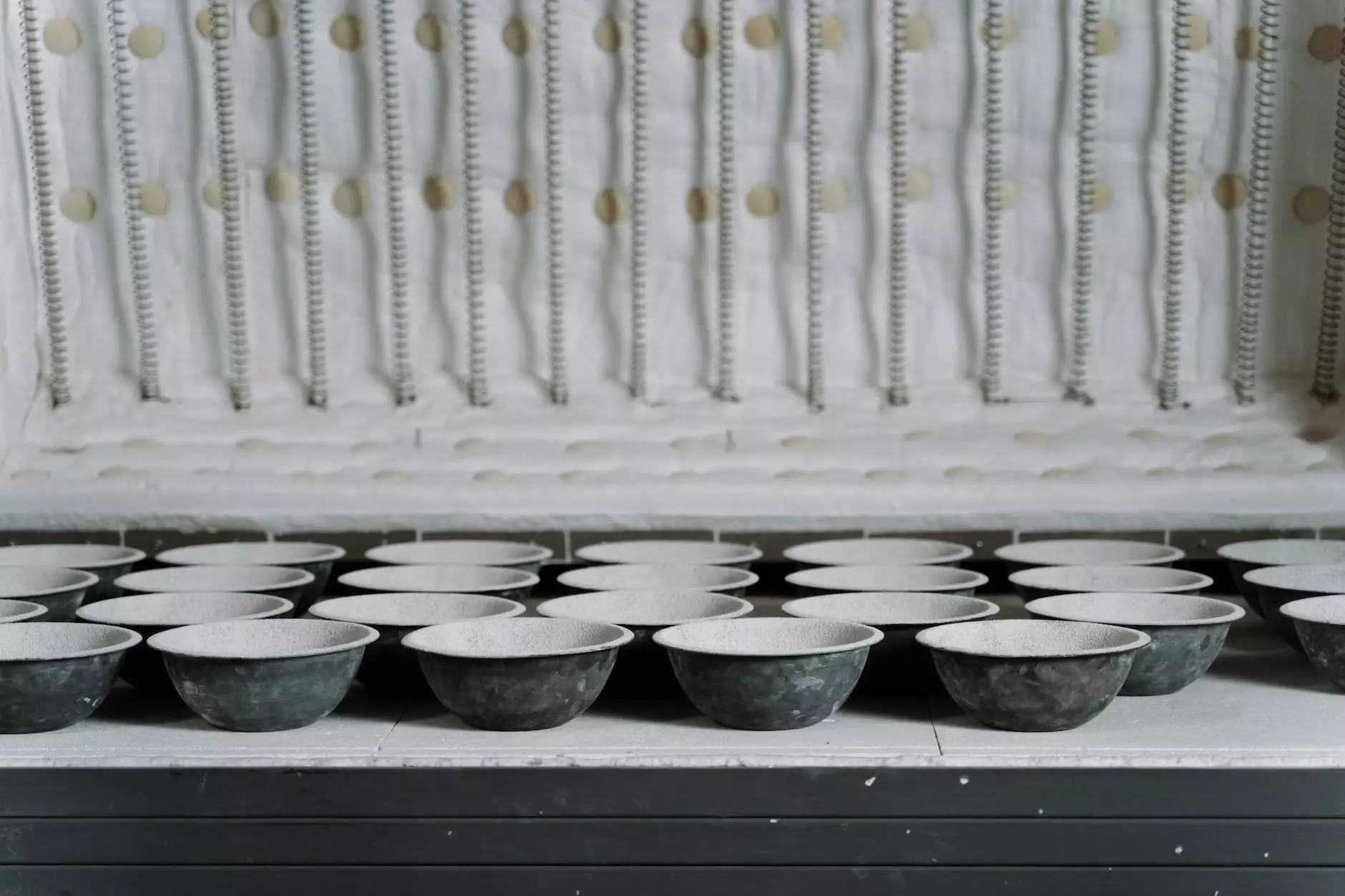

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process where plastic is heated until it becomes malleable and then injected into a metal mold. This process creates complex shapes and detailed designs that are essential in various industries. The primary materials used in this process are thermoplastics and thermosetting polymers, which provide flexibility in design and function.

The Process of Plastic Injection Molding

The plastic injection molding process can be broken down into several key steps:

- Injection: The plastic granules are fed into the injection molding machine, where they are heated until they melt.

- Injection into the mold: The molten plastic is then injected into a mold cavity under high pressure.

- Cooling: Once the mold is filled, the plastic component cools and solidifies into the desired shape.

- Ejection: After cooling, the mold opens, and the finished part is ejected.

Advantages of Using a Plastic Injection Company

Partnering with a reputable plastic injection company like DeepMould brings numerous benefits:

- High Precision: Injection molding allows for high precision and complexity in design, making it possible to produce intricate shapes and detailed designs.

- Cost-Effectiveness: Especially for large production runs, having a plastic injection company can significantly reduce costs while maintaining quality.

- Versatility: This method accommodates various types of plastics, enabling the production of diverse products, from small components to large parts.

- Reduced Waste: This efficient process reduces material waste compared to other manufacturing techniques, aligning with sustainable practices.

- Scalability: Once a mold is created, manufacturers can easily scale production to meet demand, making it ideal for growing businesses.

Applications of Plastic Injection Molding

The applications for plastic injection molding are extensive and cut across various industries. Here are a few notable sectors:

- Aerospace: Components that require precision and lightweight materials.

- Automotive: Durable parts such as dashboards, interior panels, and more.

- Consumer Goods: Everyday items including toys, containers, and appliances.

- Medical Devices: Components that must meet stringent hygiene and precision standards.

Choosing the Right Plastic Injection Company

When evaluating potential plastic injection companies, businesses should consider several critical factors:

1. Experience and Expertise

Companies like DeepMould have extensive experience in the industry, which translates to enhanced expertise. Understanding different plastics, molding techniques, and quality assurance processes can significantly affect production outcomes.

2. Quality Assurance Processes

Quality control is paramount in manufacturing. Look for a plastic injection company that implements rigorous quality assurance protocols to ensure that every part produced meets your specific standards.

3. Technology and Equipment

Advanced machinery and technology can increase efficiency and quality. A company that invests in the latest machines and software can offer faster turnaround times and better precision.

4. Customer Support

Robust customer support is crucial, especially when navigating complex projects. A solid relationship with your manufacturer can facilitate smoother operations.

The Future of Plastic Injection Molding

Looking forward, the plastic injection molding industry is poised for growth. Innovations in technology, such as 3D printing and biodegradable plastics, are creating exciting new possibilities in the realm of manufacturing. Companies that adapt and incorporate these advancements will not only enhance their competitive edge but also respond to the increasing demand for sustainable manufacturing practices.

Conclusion

In conclusion, partnering with a specialist like a plastic injection company such as DeepMould is essential for realizing the potential of high-quality plastic components in various applications. By understanding the intricacies of the plastic injection molding process, your business can unlock significant opportunities for efficiency, cost savings, and product innovation. As the industry continues to evolve, staying informed and aligned with the right partners is critical for sustainable growth and success.

Get Started with DeepMould Today

If you are looking for a reliable partner in the plastic injection molding process, visit DeepMould.net to learn more about our services and how we can help your business thrive in a competitive landscape.