Understanding Grain Bin Aeration for Optimal Farming Efficiency

Grain bin aeration is an essential component in the success of modern farming operations, particularly for those involved in grain storage. As agricultural practices evolve, understanding the intricacies of grain management becomes crucial not only for maintaining the quality of the harvest but also for maximizing profitability. This article will delve into the many aspects of grain bin aeration, detailing its importance, methods, and the overall impact it has on farming efficiency.

The Importance of Grain Bin Aeration

Grain storage is a critical aspect of the farming process. Efficient storage ensures that crops are preserved and remain in optimal condition until they can be sold or processed. Here are several reasons why grain bin aeration is vital:

- Prevention of Spoilage: Effective aeration helps to manage temperature and moisture levels within grain bins, significantly reducing the risk of spoilage.

- Quality Preservation: Proper airflow maintains the integrity and quality of the grain, preventing mold and other contaminants from diminishing its value.

- Cost Efficiency: By preventing spoilage and maintaining quality, farmers can avoid financial losses associated with damaged or degraded products.

- Enhanced Storage Life: Aeration can extend the storage life of grains, allowing farmers to hold their products until market conditions are favorable.

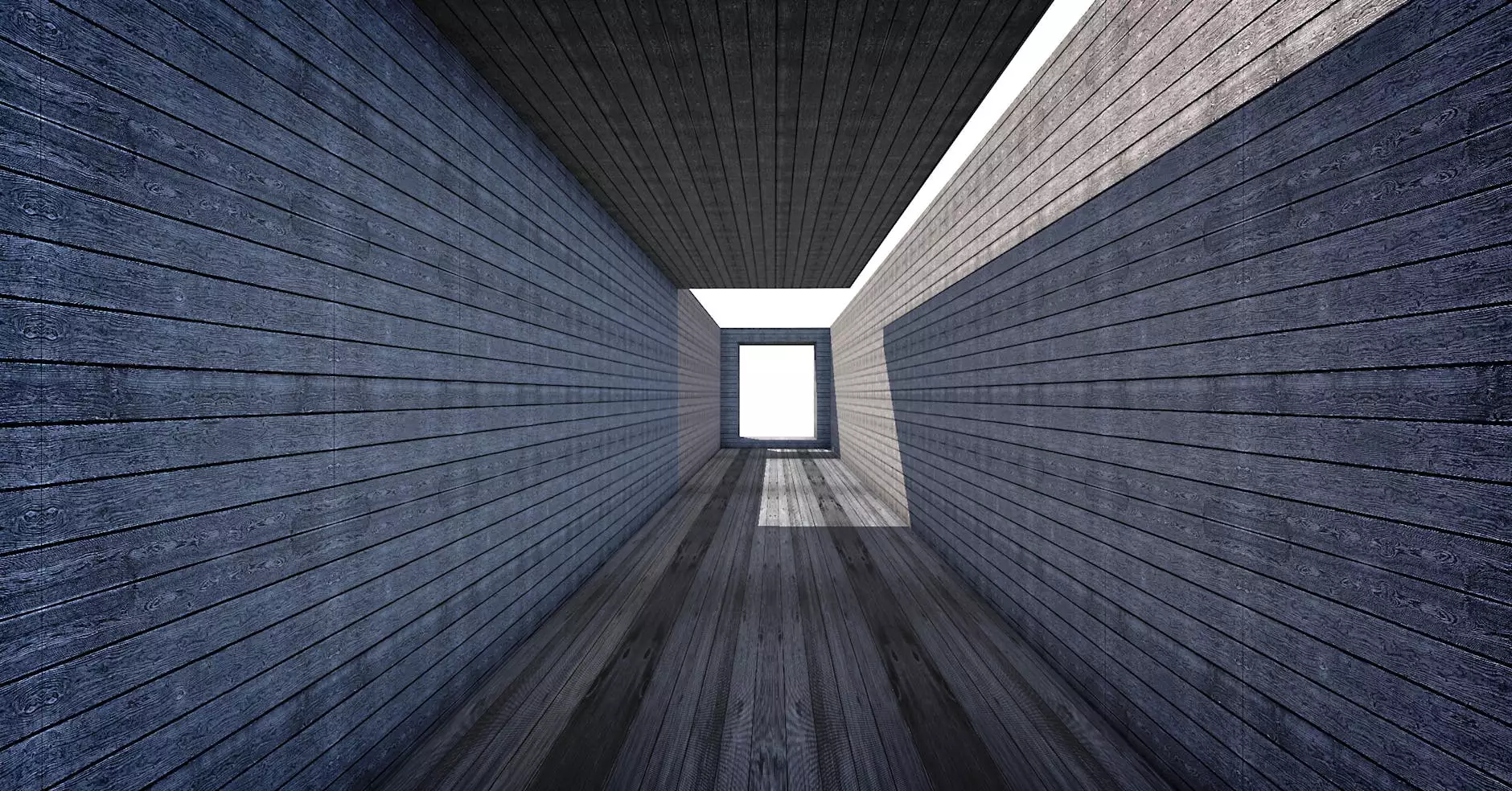

How Grain Bin Aeration Works

The primary function of grain bin aeration is to circulate air through stored grains. This air movement helps control the temperature and moisture levels in the bin, which is essential for preserving the quality of the grains. Let’s explore the mechanics of how aeration systems function:

Key Components of Aeration Systems

A typical aeration system consists of the following components:

- Fans: Powerful fans are used to push or pull air through the grain mass, ensuring that air circulates evenly.

- Ducting: Ducts or perforated floors allow airflow to permeate through the grain uniformly, preventing pockets of stale air.

- Control Systems: Modern aeration systems are often equipped with automated controls that monitor temperature and humidity, adjusting airflow as needed.

Types of Aeration Systems

There are several types of grain bin aeration systems, each designed for specific needs:

- Static Aeration: This system relies on natural convection to promote air movement without mechanical assistance. It's less effective but can be used in smaller setups.

- Forced Air Aeration: Utilizing fans, this system actively pushes air through the grain, offering superior control over temperature and moisture levels.

- Continuous vs. Batch Aeration: Continuous systems run all the time, while batch systems operate only when necessary, responding to specific conditions.

Benefits of Grain Bin Aeration

The benefits of implementing proper grain bin aeration practices are numerous:

- Improved Grain Quality: Aerated grains are less likely to experience spoilage caused by mold, fungi, or insects.

- Market Flexibility: Maintaining high-quality grain allows farmers to wait for better prices instead of rushing to sell degraded products.

- Reduced Chemical Use: Effective aeration can minimize the need for chemical treatments, which can be costly and environmentally unfriendly.

- Safety Improvements: Proper aeration reduces the chances of grain dust explosions, enhancing overall safety during storage.

Best Practices for Grain Bin Aeration

Implementing an effective grain bin aeration strategy requires understanding both the technology and the specific needs of the grains being stored. Here are some best practices to consider:

1. Regular Monitoring

To ensure that your aeration system is functioning optimally, it’s important to regularly monitor:

- Temperature: Ideal grain storage temperatures vary, but generally, they should be between 60°F to 70°F.

- Moisture Levels: Keep moisture content below 13% to prevent spoilage.

- Airflow Rates: Monitor airflow rates to ensure even distribution throughout the grain mass.

2. Invest in Quality Equipment

While it may be tempting to cut costs on aeration systems, investing in quality fans and control systems can pay dividends in the long run:

- High-Efficiency Fans: These minimize energy costs while maximizing airflow.

- Durable Materials: Choose bins and ducts made from materials that can withstand harsh agricultural conditions.

3. Conduct Routine Maintenance

Just like any machinery, aeration systems require regular upkeep. This includes:

- Clean Air Ducts: Ensure that ducts are free from blockages and debris.

- Check Electrical Connections: Regularly inspect wiring and connections to prevent system failures.

Understanding the Risks of Poor Grain Bin Aeration

Neglecting proper grain bin aeration can lead to several risks, including:

- Spoilage and Loss: Increased moisture and stagnant air can lead to significant spoilage.

- Insect Infestation: Warm, humid conditions can attract pests.

- Financial Loss: Reduced grain quality results in lower market prices, impacting profitability.

Conclusion

In conclusion, grain bin aeration stands as a pivotal element of modern agriculture. As farmers strive to deliver high-quality products to the market, effective grain management practices become increasingly crucial. By ensuring the right conditions within storage bins, farmers can not only safeguard their harvests but also enhance profitability and operational efficiency. Investing in proper aeration systems and practices will yield significant benefits for years to come.

Resources for Further Reading

- Visit TSGC INC for quality farm equipment repair and services.

- Grain Science: The Science of Grain Quality and Preservation.

- Iowa State University Extension: Resources for Grain Bin Management.