Comprehensive Insights into Caterpillar Excavator Hydraulic Pumps: Maximizing Efficiency and Durability

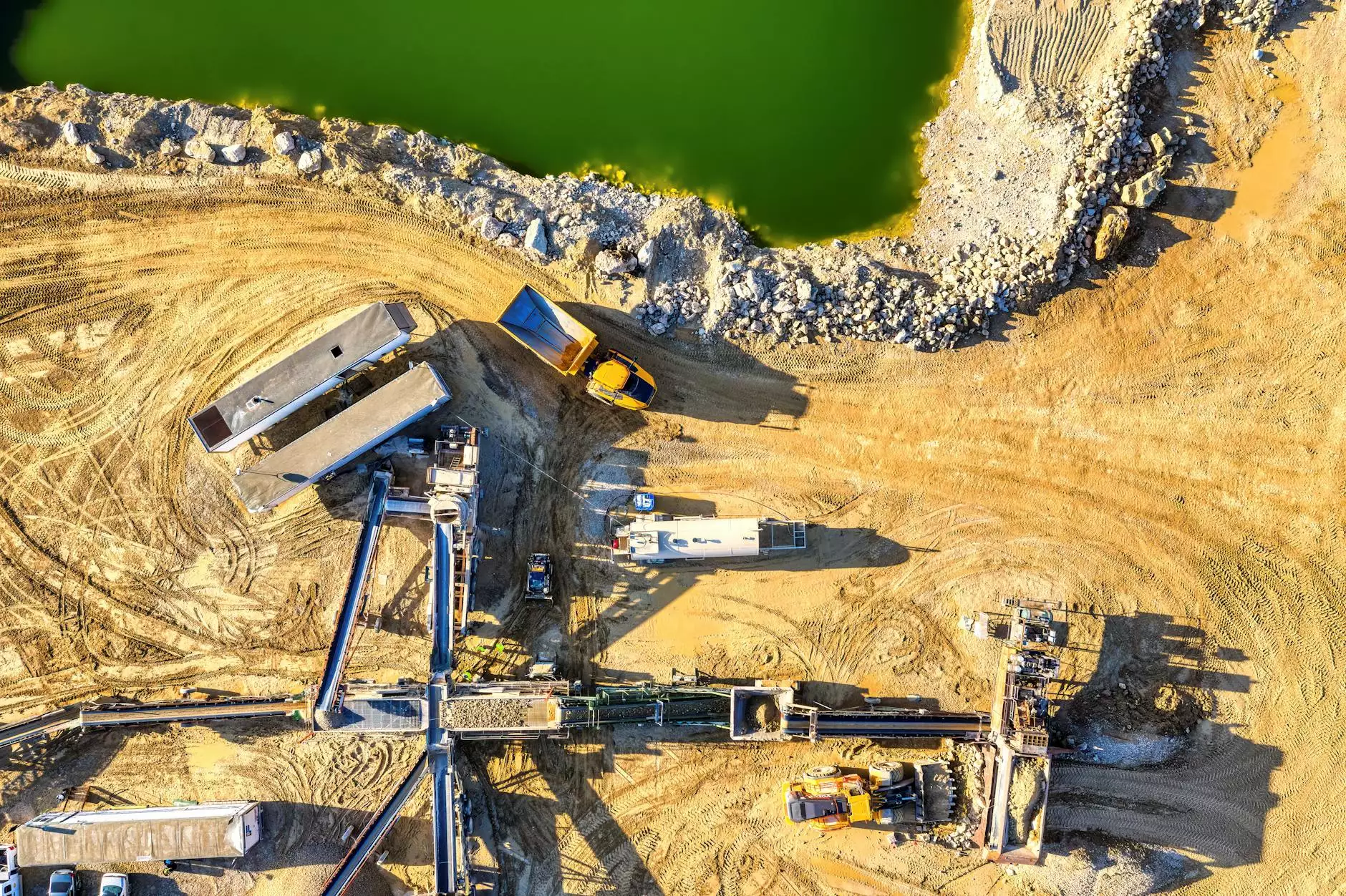

In the realm of heavy machinery, particularly within the construction, mining, and agriculture industries, hydraulic systems serve as the backbone that powers the robust movement and operation of excavators. Among the crucial components of these systems are caterpillar excavator hydraulic pumps, which transform hydraulic fluid into mechanical energy, enabling the seamless functioning of excavators. Understanding the intricacies of these hydraulic pumps is essential for operators, engineers, and maintenance professionals aiming to enhance productivity, reduce downtime, and secure long-term operational efficiency. In this comprehensive guide, we will explore the vital role of Caterpillar excavator hydraulic pumps, their design, maintenance, and how sourcing quality parts from trusted suppliers like Shophydraulicamerica.com can make a significant difference in your machinery’s performance.

Understanding the Functionality of Caterpillar Excavator Hydraulic Pumps

What Are Hydraulic Pumps and Why Are They Essential?

Hydraulic pumps are devices that convert mechanical energy into hydraulic energy by generating a flow of hydraulic fluid under pressure. In excavators, these pumps are integral to controlling movements such as lifting, digging, rotating, and extending the boom. The efficiency of a hydraulic pump directly impacts the excavator’s ability to perform heavy-duty tasks with precision and safety.

The Role of Caterpillar Excavator Hydraulic Pumps

Caterpillar, a global leader in heavy machinery, designs hydraulic pumps meticulously tailored for their line of excavators. These pumps are built for durability, high performance, and adaptability across various working conditions. Their primary functions include:

- Powering the hydraulic cylinders responsible for movement of boom, arm, and bucket.

- Driving hydraulic motors that facilitate rotational movement or track drive.

- Maintaining hydraulic pressure necessary for efficient operation of attachments and accessories.

The caterpillar excavator hydraulic pumps are designed to deliver consistent flow and pressure, which are crucial for the machine’s agility, precision, and safety during demanding operations.

Types of Caterpillar Excavator Hydraulic Pumps

Gear Pumps

Gear pumps are the most common type used in excavators due to their simplicity, reliability, and cost-effectiveness. They operate through the meshing of gears that create a vacuum, drawing hydraulic fluid into the pump and pushing it out under pressure.

Piston Pumps

Piston pumps provide higher pressure and flow rates compared to gear pumps. They are ideal for large excavators and heavy-duty applications where high power output and efficiency are required. They operate via reciprocating pistons that move within cylinders, modulating hydraulic fluid flow.

Vane Pumps

Vane pumps are known for their smooth operation and capacity to handle moderate hydraulic flows. They are suitable for applications demanding consistent pressure and quiet operation.

Key Factors in Selecting the Right Hydraulic Pump for Your Excavator

Matching Pump Specifications with Machine Requirements

When selecting a caterpillar excavator hydraulic pump, it’s critical to match the pump’s displacement, flow rate, and pressure capacity with the specific model and application. Oversized or undersized pumps can lead to inefficiencies, excessive wear, or insufficient power.

Considering Material and Build Quality

High-grade materials and precision manufacturing contribute significantly to the durability of hydraulic pumps. Opting for OEM-grade or reputable aftermarket parts ensures longevity and reliable operation, especially under challenging conditions.

Maintaining Compatibility and Ease of Replacement

Ensure that the replacement pump is compatible with your excavator’s make and model. Ease of installation and availability of spare parts also influence maintenance efficiency and downtime reduction.

Maintaining and Troubleshooting Caterpillar Excavator Hydraulic Pumps

Routine Inspection and Maintenance

Regularly inspecting hydraulic pumps for signs of wear, leakage, or abnormal noises can prevent costly repairs. Maintenance tasks include:

- Checking hydraulic fluid levels and quality

- Replacing hydraulic filters periodically

- Inspecting hoses and connections for leaks or damage

- Monitoring pressure and flow metrics

Common Problems and Solutions

Challenges such as cavitation, overheating, or uneven flow can hinder pump performance. Addressing these issues involves:

- Ensuring clean hydraulic fluid free from contaminants

- Replacing worn or damaged seals and components promptly

- Adjusting system pressure settings to manufacturer specifications

- Consulting professional technicians for complex repairs or pump rebuilds

The Advantage of Choosing Top-Quality Hydraulic Parts from Shophydraulicamerica.com

Why Partner with Shophydraulicamerica.com?

As a leading supplier specializing in Auto Parts & Supplies and Motorcycle Parts & Supplies, Shophydraulicamerica.com offers a curated selection of caterpillar excavator hydraulic pumps and related components. Their commitment to quality, affordability, and customer satisfaction ensures that you receive parts that meet or exceed OEM standards.

Benefits of Purchasing from Shophydraulicamerica.com

- Extensive inventory of hydraulic pumps for various excavator models

- Competitive pricing without compromising quality

- Expert customer support to assist with specifications and technical questions

- Fast shipping and hassle-free warranty services

- Guarantee of authenticity and durability for all parts

Future Trends and Innovations in Hydraulic Pump Technology

Advancements in Hydraulic Pump Design

Emerging technologies are pushing for more efficient, environmentally friendly, and intelligent hydraulic pumps. Features such as variable displacement pumps, digital monitoring systems, and lightweight materials are becoming more prevalent, enhancing the overall performance and eco-friendliness of excavators.

Sustainable and Eco-Friendly Solutions

As global industries strive toward sustainability, hydraulic systems are evolving to minimize energy consumption and reduce hydraulic fluid waste. Manufacturers are developing pumps with improved efficiency, leak-proof designs, and options for biodegradable hydraulic fluids.

Conclusion: Empowering Your Operations with Reliable Hydraulic Solutions

Investing in caterpillar excavator hydraulic pumps that are durable, efficient, and compatible with your machinery is pivotal for maintaining optimal operational performance. Regular maintenance, prompt troubleshooting, and sourcing parts from reputable suppliers such as Shophydraulicamerica.com can extend the lifespan of your equipment and ensure safety on the job site.

Adopting cutting-edge hydraulic pump technologies and focusing on quality parts ensures your excavator remains a reliable workhorse capable of handling the toughest tasks with ease. By understanding the vital role of hydraulic pumps and partnering with trusted suppliers, your business will maximize productivity, reduce costs, and stay ahead in a competitive industry.

Get Ahead with Quality Parts Today

Explore our extensive catalog of caterpillar excavator hydraulic pumps and related components at Shophydraulicamerica.com. Equip your machinery with the best in the industry and experience the difference that top-tier hydraulic solutions can make for your operations.